COATING

WEAR

PROTECTION

The requirements are different for every component. Our DIAPROTECT coating process is flexible and robust in extreme applications. We adapt to your needs. Please feel free to get in touch..

![]() PRODUCT

PRODUCT

SYSTEMSHEET

Dispersion coating of electroless nickel-phosphorus or electroplated nickel or nickel-phosphorus

CHARACTERISTIC:

> Wear resistant frictional pairing of metallic components

> Adjustable hardness of the nickel-phosphorous layer (approx. 550 HV0,1 to approx. 1,100 HV0,1)

> High corrosion resistance with nickel and nickel-phosphorous

> Good contour accuracy and very even layer thickness with electroless nickel

> High layer thicknesses when using nickel electroplating

APPLICATION:

Tribological pairings in systems subject to extreme stress with high friction and corrosion loads, such as in equipment for conveying raw materials in the petroleum industry, but also in equipment for manufacturing textile products.

COATING CHARACTERISTICS:

Nickel-phosphorous layer from approx. 5 μm to approx. 300 μm with dispersion materials

Nanodispersions (< 1 μm) up to dispersions > 1 – 12 μm

Coefficient of friction μ = <0,3

SUBSTRATE CHARACTERISTICS:

Electroplatable base material with adapted, defined roughness

![]() PRODUCT

PRODUCT

SYSTEMSHEET

+ Heavy-duty wear protection with diamond

+ As a thin-film system (10-30 μ)

+ As a thick-film system (30–100 μ) or higher

+ Protection against particle and chemical wear

+ Works on all substrates

+ Effective combination of the key characteristics

Wear protection and corrosion protection of metal surfaces

+ Cost reduction compared to changing the

substrate material

+ Use without design changes

+ Not sensitive to lubricants

+ Increased safety factor

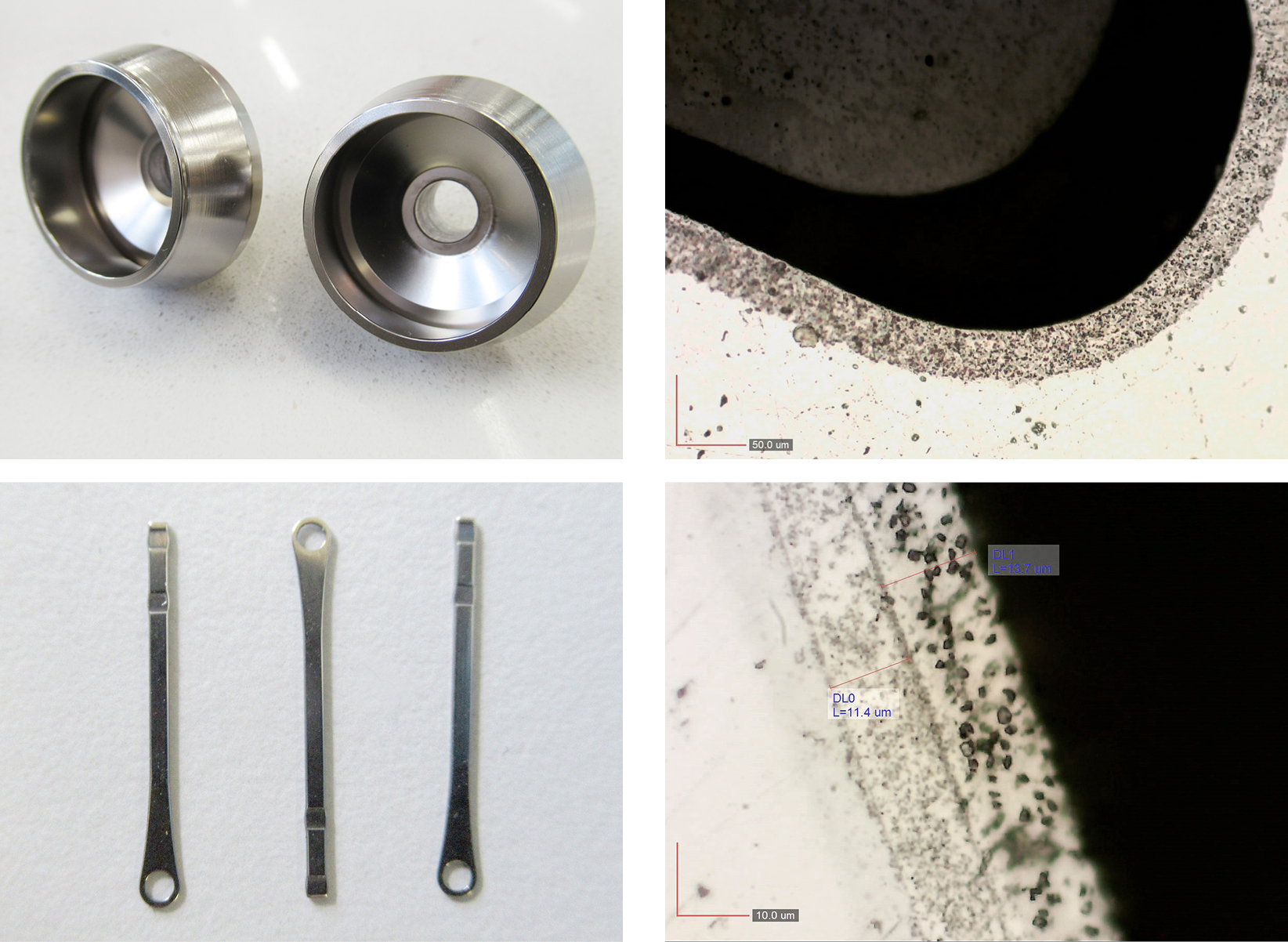

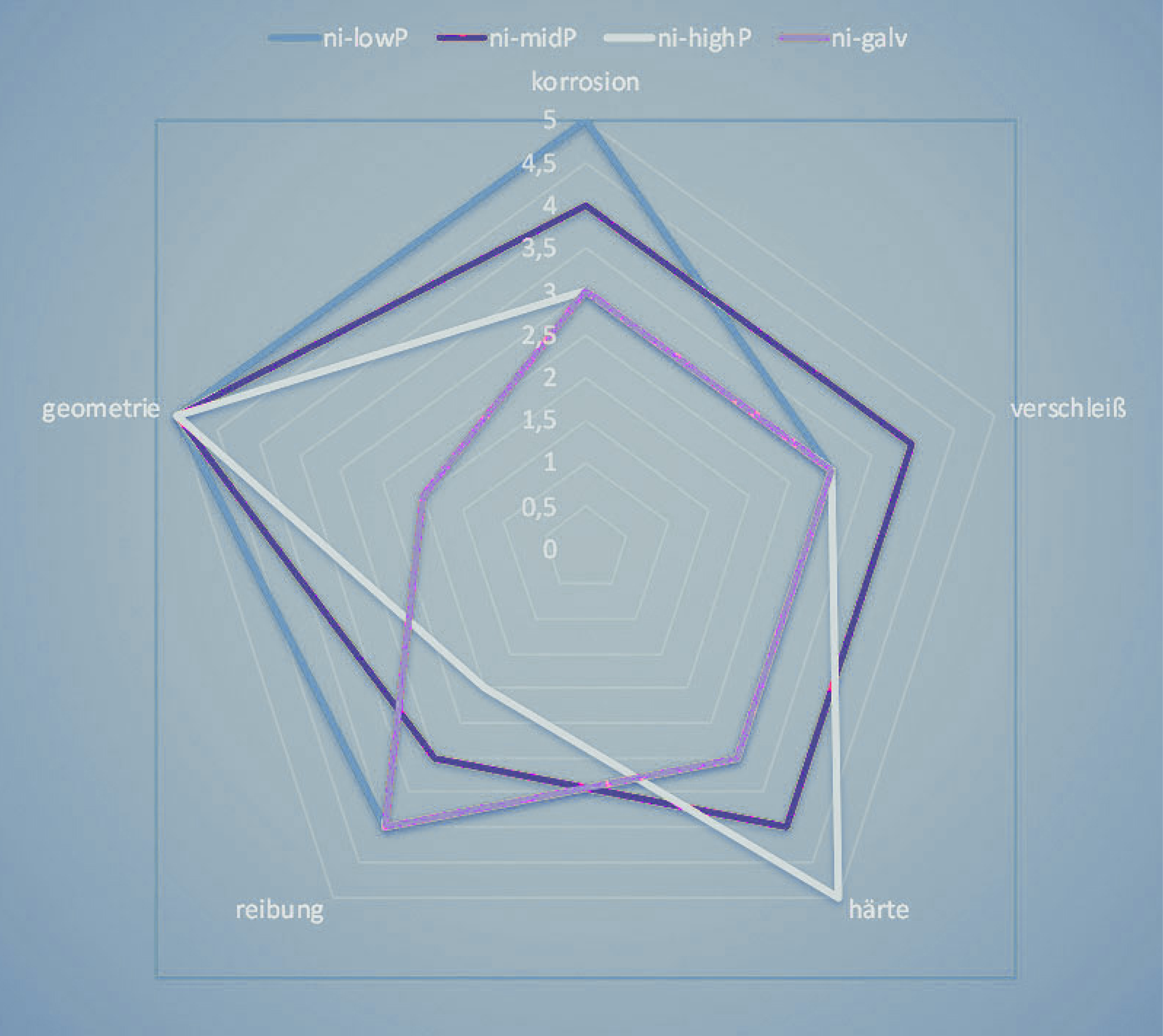

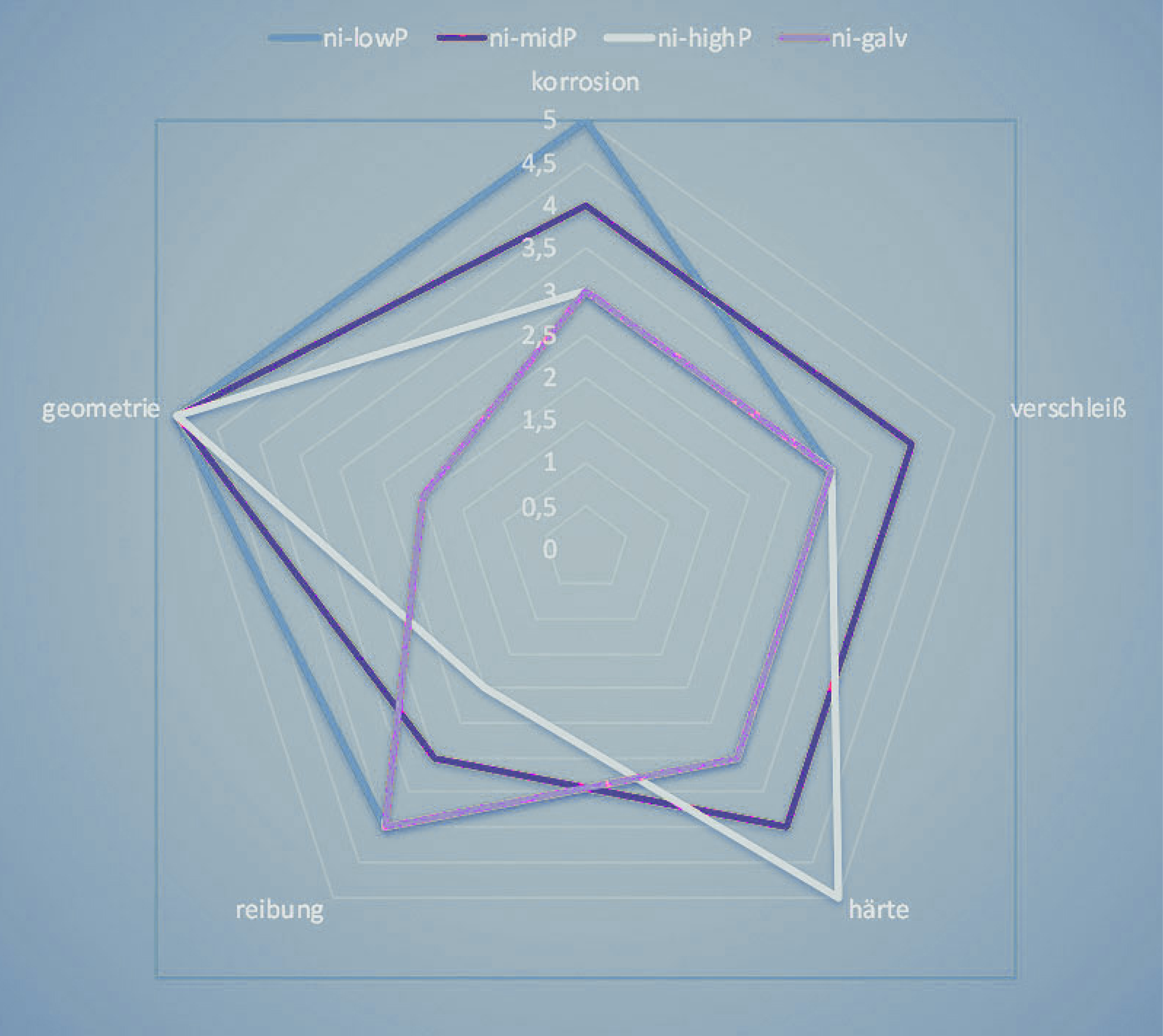

Coatings based on nickel and nickel-phosphorus stand out for combining multiple important characteristics and for allowing thesecharacteristics to be adapted to specific applications based on their composition and/or heat treatment. . This can be illustrated by means of a network diagram for qualitative evaluation, on the basis of which the user can select the required properties.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

APPLICATION

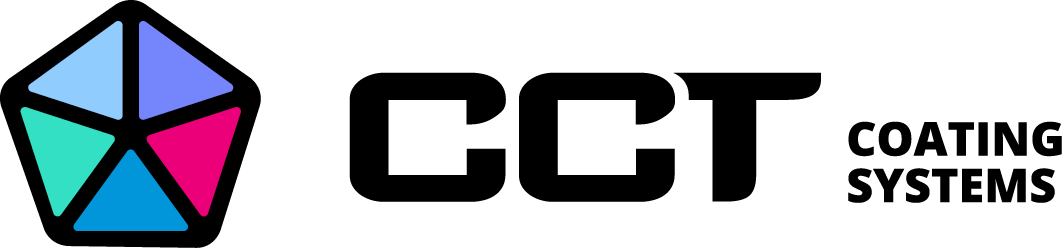

As a rule, there are movements between parts of equipment or sliding and friction processes between equipment and the products to be machined in a wide variety of equipment and systems. In the majority of cases, this results in more or less pronounced wear on parts of the equipment. Such wear loads can occur, for example, in equipment for the extraction of raw materials in the petroleum industry, but also in the manufacture of textile products.

To maintain the functionality of equipment and systems, wear on such contact surfaces must be effectively prevented or reduced. Electroless and electroplated nickel and nickel-phosphorus coatings are very suitable as surface protection.

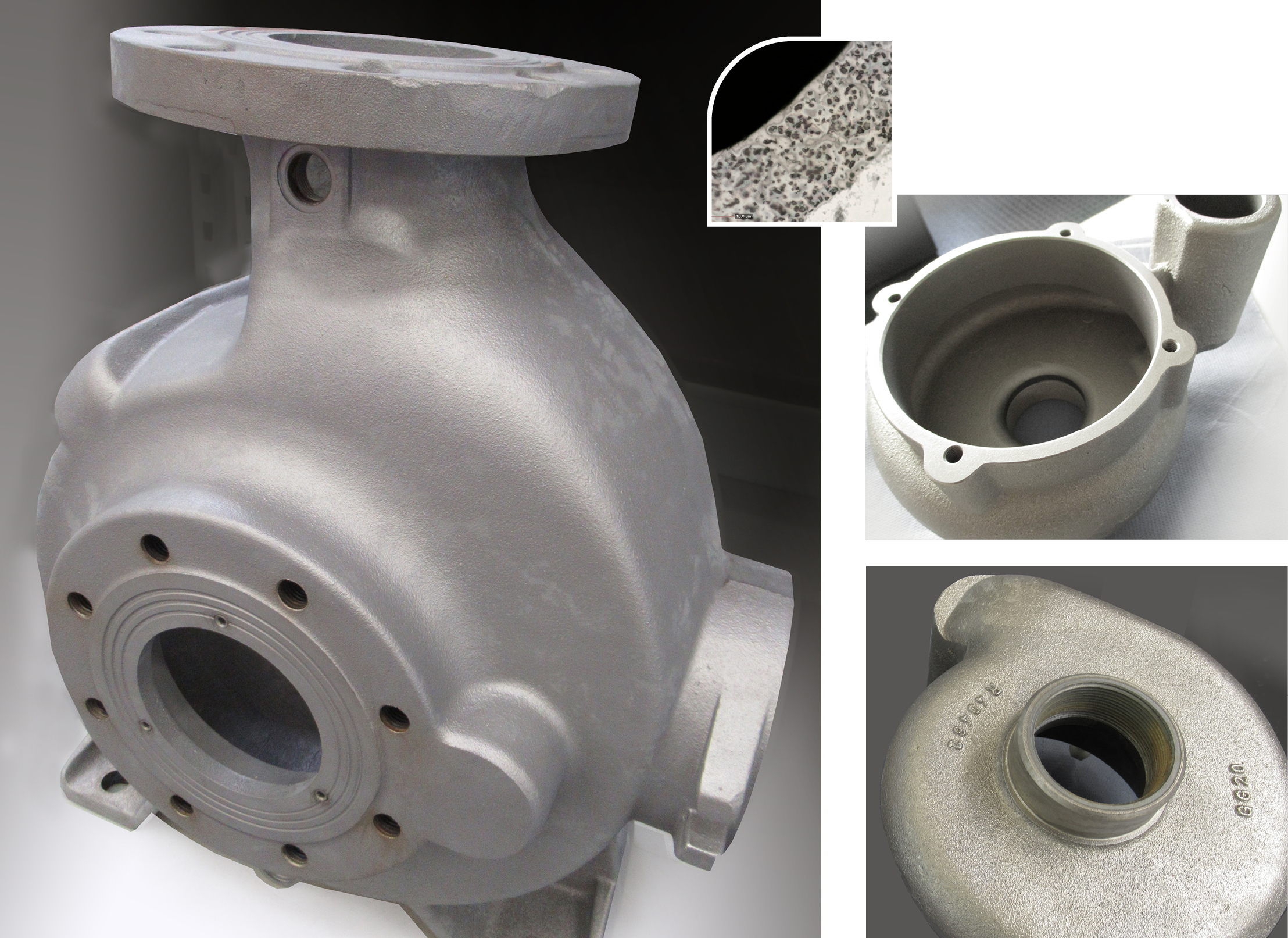

DIAPROTECT®-coatings were specially developed to protect against heavy abrasive and chemical wear.

The hardness of a DIAPROTECT®-coating can be adjusted to values between approx. 500 HV and 1,100 HV depending on the phosphorus content and after-treatment. This means that surfaces can be adapted to the respective type of load, e.g. different frictional stresses or different mechanical loads or chemical resistance. DIAPROTECT® achieves the highest wear resistance primarily through its dispersion coating design, in which diamond is predominantly used as embedded particles. The layers are deposited in thicknesses from about 10 µm to several hundred micrometres.

In addition to the good wear resistance, DIAPROTECT®coatings are also characterised by a very high level of corrosion resistance, whereby excellent durability is achieved for many technical applications.

Typical applications for DIAPROTECT®-coatings:

> Pump bodies and rotors in the chemical industry

> Parts in the textile industry subject to heavy wear

> Components used in crude oil and natural gas delivery and the chemical industry

Optimisation through combination: A combination coating with a thickness of up to 10 μm with DIASHIELD® can be used to reduce surface roughness. This can be attributed to a substrate that is too rough or to the deposition of DIAPROTECT®-coatings with thicknesses significantly greater than 20 µm.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

The coatings for increasing wear resistance are available in variants with different compositions, different types of deposition and in combination with dispersion coatings with different types of dispersion materials. The type of coating to be used depends on the load at the place of use and can consist of both wear load and corrosion load.

| Functional properties | Friction-enhancingDIAPROTECT® diamond coating |

| Designation | DIAPROTECT NANO | DIAPROTECT 2D | DIAPROTECT 10D |

| Average particle size | 0,5 μm | 2 μm | 10 μm |

| Coating rate | 15 % and 60 % | 15 % and 60 % | 15 % and 60 % |

| Layer material | Electroless nickel-phosphorus or electroplated nickel or nickel-phosphorus. |

| Hardness of coating matrix | 550 – 1.000 HV0,1 |

| Layer thickness of the matrix (electroless nickel) | 10 – 300 μm | 10 – 300 μm | 10 – 300 μm |

| Layer thickness of the matrix (electroplated nickel) | up to several hundred microns |

The thickness of the nickel layer is chosen so that the particles (e.g. diamond) are homogeneously incorporated into the layer.

Another characteristic value of the coating is provided by the electroless nickel coating (as far as it is used for the coating) with phosphorus contents between 2 % and up to 13 %, available in three state forms:

> Low phosphorous content – 2 % to 5 % / high deposition hardness / low corrosion resistance

> Medium phosphorous content – 5 % to 10 % / medium deposition hardness / high corrosion resistance

> High phosphorous content – 10 % to 13 % / low deposition hardness / high corrosion resistance

The phosphorous content determines the basic hardness of the nickel layer, the maximum hardness that can be achieved using temperature treatment, and the corrosion resistance.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

REQUIREMENTS FOR WEAR-ENHANCING COATINGS

The characteristic of enhancing the wear-resistance of a surface is linked to certain design requirements:

> Suitability for electroplating – the substrate material must be suitable for electroplating, which is primarily reflected by very good adhesion of the coating to the substrate. The suitability for electroplating with DIAPROTECT® must be clarified with the client in advance.

> Sufficient load-bearing capacity of the substrate – the substrate must have sufficient load-bearing capacity to prevent excessive deformation with the associated collapse of the coating.

> Hardness of the surface of the contact surfaces – when using a DIAPROTECT®-dispersion coating, the interlocking between the hard materials (e.g. diamond) of the dispersion coating (usually a nickel or nickel-phosphorus layer) and the surface of the component is determined by the surface hardness of the component. A higher surface hardness makes it more difficult for the diamonds to penetrate the component surface. A lower surface hardness increases the shearing (in the form of material wear) of material of the component due to (friction) wear.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

SOLUTION EXAMPLES

THERE IS ALWAYS A CUSTOM SOLUTION

The requirements are different for every component. Our DIAPROTECT coating process is flexible and robust in extreme applications. We adapt to your needs. Please feel free to get in touch..

![]() PRODUCT

PRODUCT

SYSTEMSHEET

AT A GLANCE

Dispersion coating of electroless nickel-phosphorus or electroplated nickel or nickel-phosphorus

CHARACTERISTIC:

> Wear resistant frictional pairing of metallic components

> Adjustable hardness of the nickel-phosphorous layer (approx. 550 HV0,1 to approx. 1,100 HV0,1)

> High corrosion resistance with nickel and nickel-phosphorous

> Good contour accuracy and very even layer thickness with electroless nickel

> High layer thicknesses when using nickel electroplating

APPLICATION:

Tribological pairings in systems subject to extreme stress with high friction and corrosion loads, such as in equipment for conveying raw materials in the petroleum industry, but also in equipment for manufacturing textile products.

COATING CHARACTERISTICS:

Nickel-phosphorous layer from approx. 5 μm to approx. 300 μm with dispersion materials

Nanodispersions (< 1 μm) up to dispersions > 1 – 12 μm

Coefficient of friction μ = <0,3

SUBSTRATE CHARACTERISTICS:

Electroplatable base material with adapted, defined roughness

![]() PRODUCT

PRODUCT

SYSTEMSHEET

ADVANTAGES

ADVANTAGES OF USING DIAPROTECT COATINGS:

+ Heavy-duty wear protection with diamond

+ As a thin-film system (10-30 μ)

+ As a thick-film system (30–100 μ) or higher

+ Protection against particle and chemical wear

+ Works on all substrates

+ Effective combination of the key characteristics

Wear protection and corrosion protection of metal surfaces

+ Cost reduction compared to changing the

substrate material

+ Use without design changes

+ Not sensitive to lubricants

+ Increased safety factor

Coatings based on nickel and nickel-phosphorus stand out for combining multiple important characteristics and for allowing thesecharacteristics to be adapted to specific applications based on their composition and/or heat treatment. . This can be illustrated by means of a network diagram for qualitative evaluation, on the basis of which the user can select the required properties.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

APPLICATIONS

As a rule, there are movements between parts of equipment or sliding and friction processes between equipment and the products to be machined in a wide variety of equipment and systems. In the majority of cases, this results in more or less pronounced wear on parts of the equipment. Such wear loads can occur, for example, in equipment for the extraction of raw materials in the petroleum industry, but also in the manufacture of textile products.

To maintain the functionality of equipment and systems, wear on such contact surfaces must be effectively prevented or reduced. Electroless and electroplated nickel and nickel-phosphorus coatings are very suitable as surface protection.

DIAPROTECT®-coatings were specially developed to protect against heavy abrasive and chemical wear.

The hardness of a DIAPROTECT®-coating can be adjusted to values between approx. 500 HV and 1,100 HV depending on the phosphorus content and after-treatment. This means that surfaces can be adapted to the respective type of load, e.g. different frictional stresses or different mechanical loads or chemical resistance. DIAPROTECT® achieves the highest wear resistance primarily through its dispersion coating design, in which diamond is predominantly used as embedded particles. The layers are deposited in thicknesses from about 10 µm to several hundred micrometres.

In addition to the good wear resistance, DIAPROTECT®coatings are also characterised by a very high level of corrosion resistance, whereby excellent durability is achieved for many technical applications.

Typical applications for DIAPROTECT®-coatings:

> Pump bodies and rotors in the chemical industry

> Parts in the textile industry subject to heavy wear

> Components used in crude oil and natural gas delivery and the chemical industry

Optimisation through combination: A combination coating with a thickness of up to 10 μm with DIASHIELD® can be used to reduce surface roughness. This can be attributed to a substrate that is too rough or to the deposition of DIAPROTECT®-coatings with thicknesses significantly greater than 20 µm.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

PARAMETERS

The coatings for increasing wear resistance are available in variants with different compositions, different types of deposition and in combination with dispersion coatings with different types of dispersion materials. The type of coating to be used depends on the load at the place of use and can consist of both wear load and corrosion load.

| Functional properties | Friction-enhancingDIAPROTECT® diamond coating |

| Designation | DIAPROTECT NANO | DIAPROTECT 2D | DIAPROTECT 10D |

| Average particle size | 0,5 μm | 2 μm | 10 μm |

| Coating rate | 15 % and 60 % | 15 % and 60 % | 15 % and 60 % |

| Layer material | Electroless nickel-phosphorus or electroplated nickel or nickel-phosphorus. |

| Hardness of coating matrix | 550 – 1.000 HV0,1 |

| Layer thickness of the matrix (electroless nickel) | 10 – 300 μm | 10 – 300 μm | 10 – 300 μm |

| Layer thickness of the matrix (electroplated nickel) | up to several hundred microns |

The thickness of the nickel layer is chosen so that the particles (e.g. diamond) are homogeneously incorporated into the layer.

Another characteristic value of the coating is provided by the electroless nickel coating (as far as it is used for the coating) with phosphorus contents between 2 % and up to 13 %, available in three state forms:

> Low phosphorous content – 2 % to 5 % / high deposition hardness / low corrosion resistance

> Medium phosphorous content – 5 % to 10 % / medium deposition hardness / high corrosion resistance

> High phosphorous content – 10 % to 13 % / low deposition hardness / high corrosion resistance

The phosphorous content determines the basic hardness of the nickel layer, the maximum hardness that can be achieved using temperature treatment, and the corrosion resistance.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

REQUIREMENTS

REQUIREMENTS FOR WEAR-ENHANCING COATINGS

The characteristic of enhancing the wear-resistance of a surface is linked to certain design requirements:

> Suitability for electroplating – the substrate material must be suitable for electroplating, which is primarily reflected by very good adhesion of the coating to the substrate. The suitability for electroplating with DIAPROTECT® must be clarified with the client in advance.

> Sufficient load-bearing capacity of the substrate – the substrate must have sufficient load-bearing capacity to prevent excessive deformation with the associated collapse of the coating.

> Hardness of the surface of the contact surfaces – when using a DIAPROTECT®-dispersion coating, the interlocking between the hard materials (e.g. diamond) of the dispersion coating (usually a nickel or nickel-phosphorus layer) and the surface of the component is determined by the surface hardness of the component. A higher surface hardness makes it more difficult for the diamonds to penetrate the component surface. A lower surface hardness increases the shearing (in the form of material wear) of material of the component due to (friction) wear.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

SOLUTION EXAMPLES

The requirements are different for every component. Our DIAPROTECT coating process is flexible and robust in extreme applications. We adapt to your needs. Please feel free to get in touch..

![]() PRODUCT

PRODUCT

SYSTEMSHEET

AT A GLANCE

Dispersion coating of electroless nickel-phosphorus or electroplated nickel or nickel-phosphorus

CHARACTERISTIC:

> Wear resistant frictional pairing of metallic components

> Adjustable hardness of the nickel-phosphorous layer (approx. 550 HV0,1 to approx. 1,100 HV0,1)

> High corrosion resistance with nickel and nickel-phosphorous

> Good contour accuracy and very even layer thickness with electroless nickel

> High layer thicknesses when using nickel electroplating

APPLICATION:

Tribological pairings in systems subject to extreme stress with high friction and corrosion loads, such as in equipment for conveying raw materials in the petroleum industry, but also in equipment for manufacturing textile products.

COATING CHARACTERISTICS:

Nickel-phosphorous layer from approx. 5 μm to approx. 300 μm with dispersion materials

Nanodispersions (< 1 μm) up to dispersions > 1 – 12 μm

Coefficient of friction μ = <0,3

SUBSTRATE CHARACTERISTICS:

Electroplatable base material with adapted, defined roughness

![]() PRODUCT

PRODUCT

SYSTEMSHEET

ADVANTAGES

+ Heavy-duty wear protection with diamond

+ As a thin-film system (10-30 μ)

+ As a thick-film system (30–100 μ) or higher

+ Protection against particle and chemical wear

+ Works on all substrates

+ Effective combination of the key characteristics

Wear protection and corrosion protection of metal surfaces

+ Cost reduction compared to changing the

substrate material

+ Use without design changes

+ Not sensitive to lubricants

+ Increased safety factor

Coatings based on nickel and nickel-phosphorus stand out for combining multiple important characteristics and for allowing thesecharacteristics to be adapted to specific applications based on their composition and/or heat treatment. . This can be illustrated by means of a network diagram for qualitative evaluation, on the basis of which the user can select the required properties.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

APPLICATIONS

As a rule, there are movements between parts of equipment or sliding and friction processes between equipment and the products to be machined in a wide variety of equipment and systems. In the majority of cases, this results in more or less pronounced wear on parts of the equipment. Such wear loads can occur, for example, in equipment for the extraction of raw materials in the petroleum industry, but also in the manufacture of textile products.

To maintain the functionality of equipment and systems, wear on such contact surfaces must be effectively prevented or reduced. Electroless and electroplated nickel and nickel-phosphorus coatings are very suitable as surface protection.

DIAPROTECT®-coatings were specially developed to protect against heavy abrasive and chemical wear.

The hardness of a DIAPROTECT®-coating can be adjusted to values between approx. 500 HV and 1,100 HV depending on the phosphorus content and after-treatment. This means that surfaces can be adapted to the respective type of load, e.g. different frictional stresses or different mechanical loads or chemical resistance. DIAPROTECT® achieves the highest wear resistance primarily through its dispersion coating design, in which diamond is predominantly used as embedded particles. The layers are deposited in thicknesses from about 10 µm to several hundred micrometres.

In addition to the good wear resistance, DIAPROTECT®coatings are also characterised by a very high level of corrosion resistance, whereby excellent durability is achieved for many technical applications.

Typical applications for DIAPROTECT®-coatings:

> Pump bodies and rotors in the chemical industry

> Parts in the textile industry subject to heavy wear

> Components used in crude oil and natural gas delivery and the chemical industry

Optimisation through combination: A combination coating with a thickness of up to 10 μm with DIASHIELD® can be used to reduce surface roughness. This can be attributed to a substrate that is too rough or to the deposition of DIAPROTECT®-coatings with thicknesses significantly greater than 20 µm.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

PARAMETERS

The coatings for increasing wear resistance are available in variants with different compositions, different types of deposition and in combination with dispersion coatings with different types of dispersion materials. The type of coating to be used depends on the load at the place of use and can consist of both wear load and corrosion load.

| Functional properties | Friction-enhancingDIAPROTECT® diamond coating |

| Designation | DIAPROTECT NANO | DIAPROTECT 2D | DIAPROTECT 10D |

| Average particle size | 0,5 μm | 2 μm | 10 μm |

| Coating rate | 15 % and 60 % | 15 % and 60 % | 15 % and 60 % |

| Layer material | Electroless nickel-phosphorus or electroplated nickel or nickel-phosphorus. |

| Hardness of coating matrix | 550 – 1.000 HV0,1 |

| Layer thickness of the matrix (electroless nickel) | 10 – 300 μm | 10 – 300 μm | 10 – 300 μm |

| Layer thickness of the matrix (electroplated nickel) | up to several hundred microns |

The thickness of the nickel layer is chosen so that the particles (e.g. diamond) are homogeneously incorporated into the layer.

Another characteristic value of the coating is provided by the electroless nickel coating (as far as it is used for the coating) with phosphorus contents between 2 % and up to 13 %, available in three state forms:

> Low phosphorous content – 2 % to 5 % / high deposition hardness / low corrosion resistance

> Medium phosphorous content – 5 % to 10 % / medium deposition hardness / high corrosion resistance

> High phosphorous content – 10 % to 13 % / low deposition hardness / high corrosion resistance

The phosphorous content determines the basic hardness of the nickel layer, the maximum hardness that can be achieved using temperature treatment, and the corrosion resistance.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

REQUIREMENTS

REQUIREMENTS FOR WEAR-ENHANCING COATINGS

The characteristic of enhancing the wear-resistance of a surface is linked to certain design requirements:

> Suitability for electroplating – the substrate material must be suitable for electroplating, which is primarily reflected by very good adhesion of the coating to the substrate. The suitability for electroplating with DIAPROTECT® must be clarified with the client in advance.

> Sufficient load-bearing capacity of the substrate – the substrate must have sufficient load-bearing capacity to prevent excessive deformation with the associated collapse of the coating.

> Hardness of the surface of the contact surfaces – when using a DIAPROTECT®-dispersion coating, the interlocking between the hard materials (e.g. diamond) of the dispersion coating (usually a nickel or nickel-phosphorus layer) and the surface of the component is determined by the surface hardness of the component. A higher surface hardness makes it more difficult for the diamonds to penetrate the component surface. A lower surface hardness increases the shearing (in the form of material wear) of material of the component due to (friction) wear.

![]() PRODUCT

PRODUCT

SYSTEMSHEET