THERE IS ALWAYS A CUSTOM-TAILORED SOLUTION

The requirements are different for each component. Our DIAGRIP coating process is flexible.

We adapt to your needs. Please feel free to get in touch.

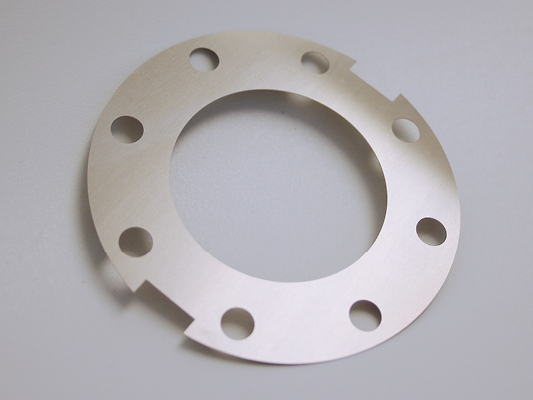

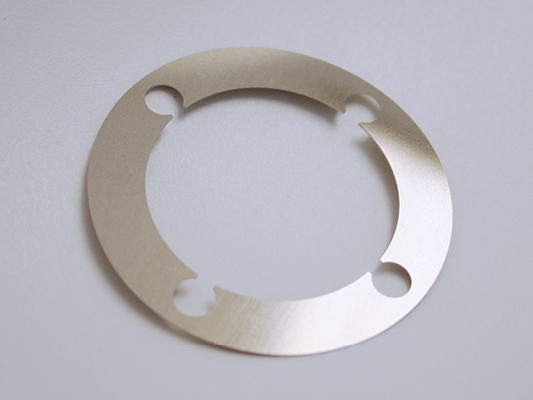

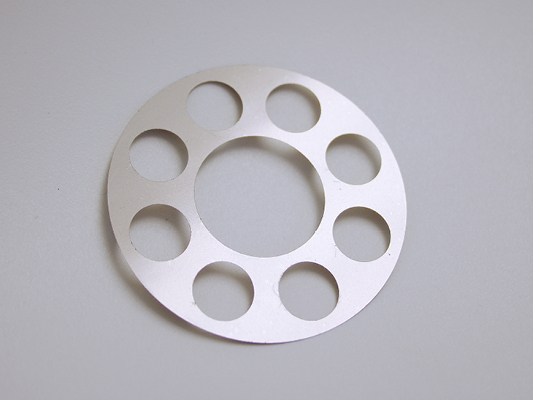

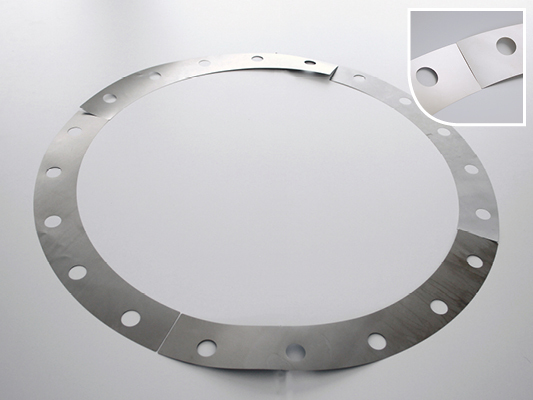

Large-format friction shims are used up to diameters of more than 2000 mm. Due to the segmentation of the discs and intelligent fixing profiles in the segments, they can be easily handled during assembly. The thickness of the discs can range from 0.1 mm to 50 mm. The discs and segments can be reused if handled properly.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

Dispersion coating of nickel-phosphorus with diamond on substrate material (C75/C100/CU/Ni/stainless steel/plastic):

CHARACTERISTIC:

> Increased adhesion, detachable contact surface

> Adjustable hardness of the nickel-phosphorous layer (approx. 550 HV0,1 to approx. 950 HV0,1)

> High corrosion resistance

> Good contour accuracy and very even thickness of the nickel coating

> Can be used with existing designs

APPLICATION:

Transmission of forces and torques in functional systems for the production of force-locking composite systems with screw connection, press connection or flange connection.

COATING CHARACTERISTICS:

Nickel-phosphorus layer from approx. 5 μm to approx. 22 μm with diamond grain size between 10 µm and 35 µm (layer thickness/grain size matched to each other), larger grain sizes (> 35 µm – 80 µm) as special solution

Friction value μ = 0.5 – 0.8

SUBSTRATE CHARACTERISTICS:

Electroplatable base material with adapted, defined roughness

![]() PRODUCT SYSTEM SHEET

PRODUCT SYSTEM SHEET

+ Increase in the transmittable forces by 0.5 – 0.8 μ and torques of a connection via flange unit, as well as resulting reduction in component sizes and weights

+ 3 to 4 times higher transmittable torque

+ Direct coating, as a friction shim or foil

+ Can be used with components in any shape & size

+ Increase in the safety factor

+ Reduction in cost for individual components

+ Easy handling

+ Not sensitive to lubricants

+ Normally reusable after disassembly

+ Usable without additional work

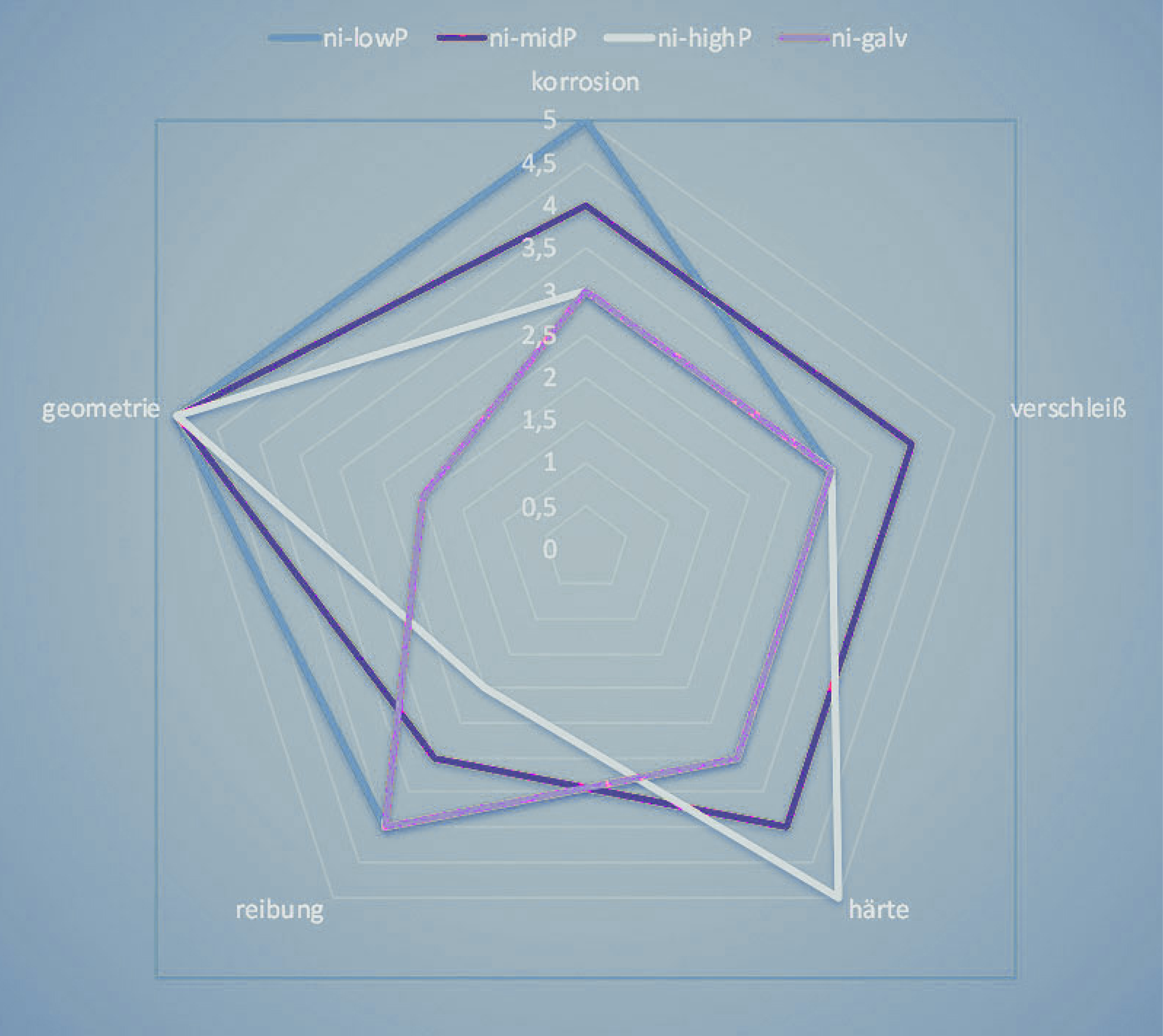

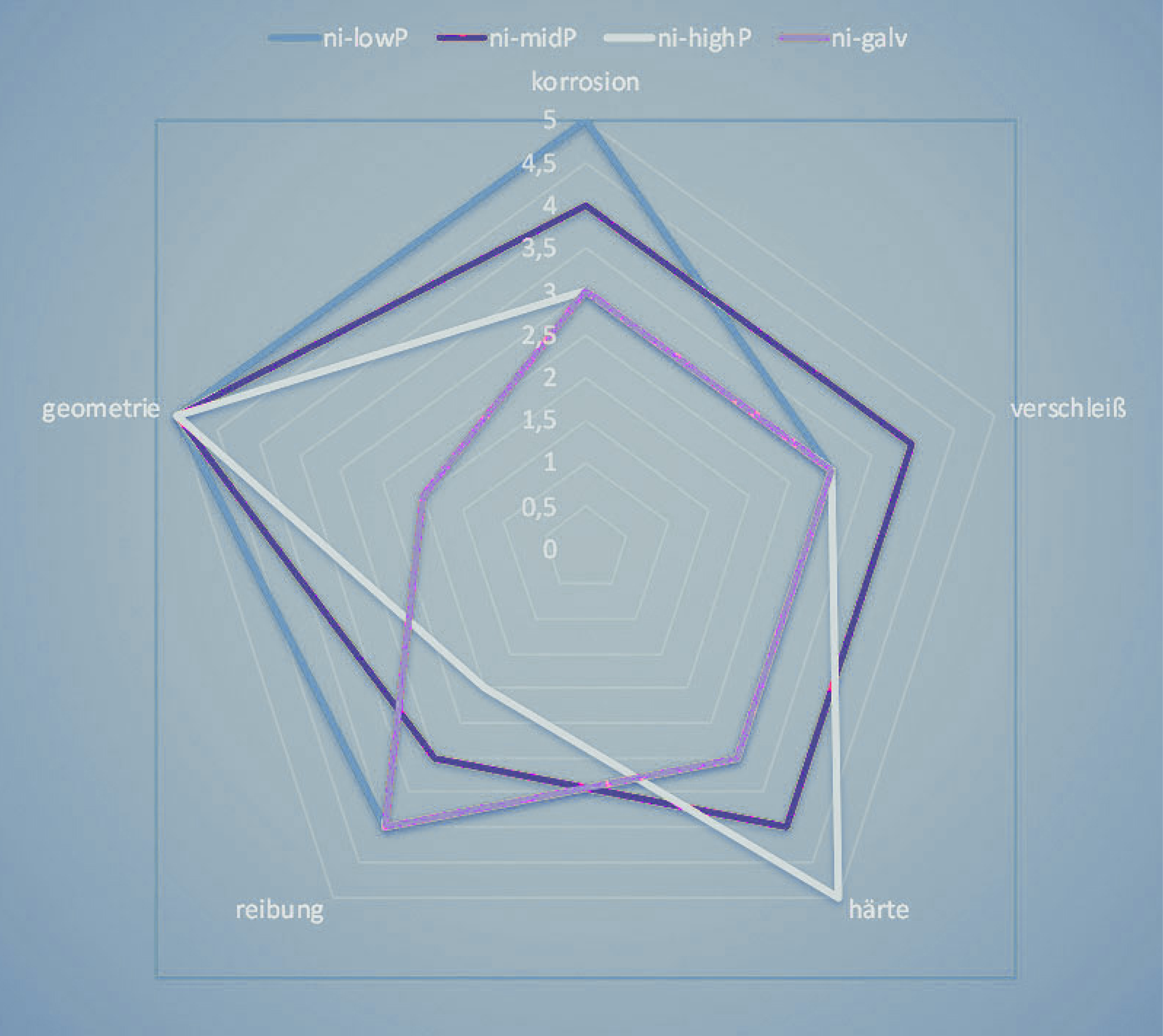

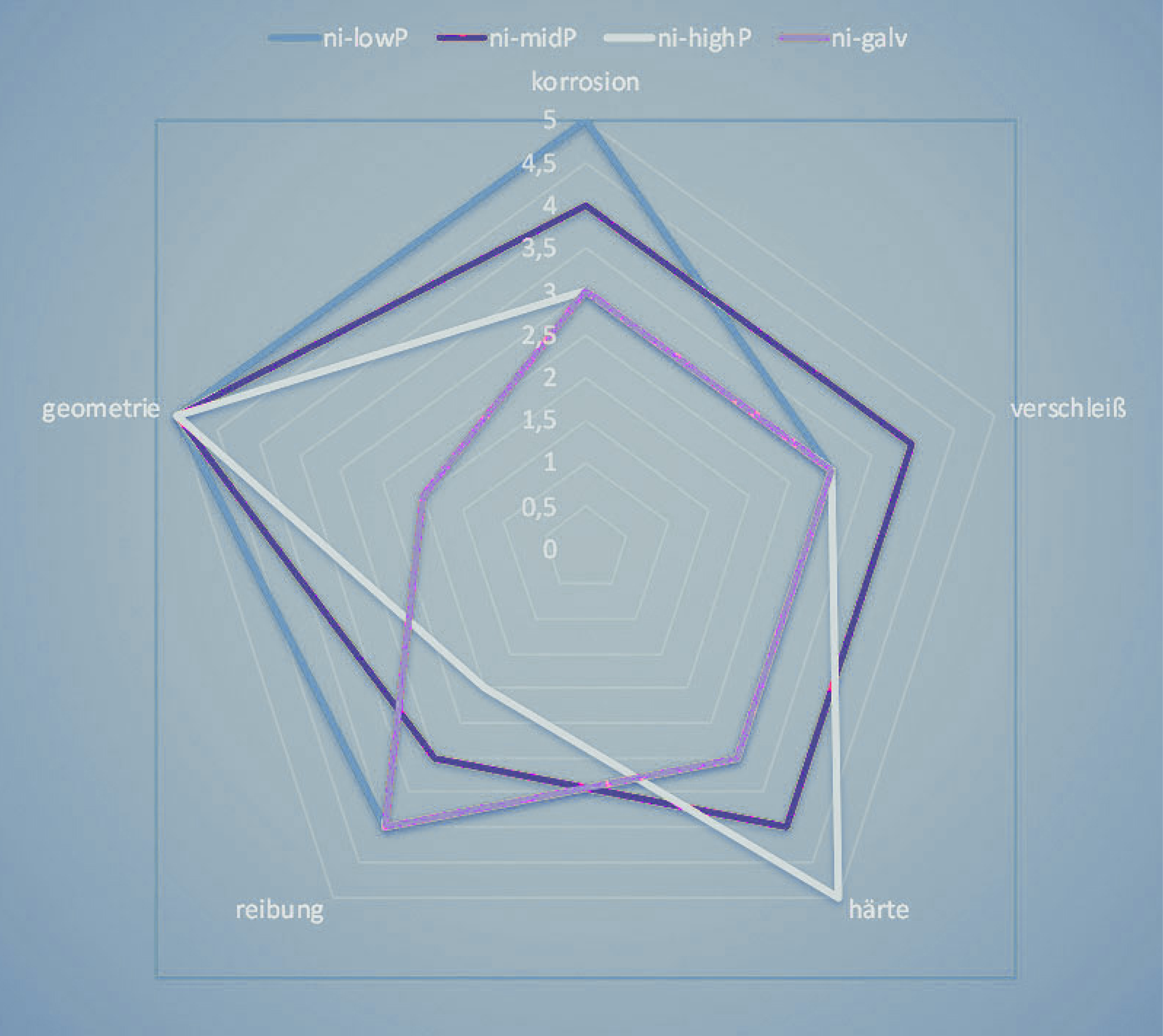

Coatings based on nickel and nickel-phosphorus stand out for combining multiple important characteristics, and for allowing these characteristics to be adapted to specific applications based on their composition and/or heat treatment. This can be illustrated by means of a network diagram for qualitative evaluation, on the basis of which the user can select the required properties.

![]() PRODUCT SYSTEM SHEET

PRODUCT SYSTEM SHEET

The dynamic transmission of mechanical forces and torques in machines can be achieved, among other things, by connecting the drive and machine elements by pressing two (usually rotating) surfaces onto each other. Depending on the design of the machines, permanently working but detachable or cyclically working transmission designs are used. Examples include flange connections, face press connections, shaft-hub connections, but also screw connections, which are usually permanent. Cyclically operating systems for power and torque transmission, for example, consist of two discs pressed onto each other.

In all cases, the efficiency of the power or torque transmission is subject to the requirement that friction is largely eliminated..The relevant parameters of power transmission include, above all, the available surface area of the two contact partners (drive and counterpart). The more efficiently friction or slip is prevented, the smaller and thus lighter the two contact partners can be designed to be – increasing the coefficient of friction thus offers a decisive contribution to energy and material savings in system and machine construction. The increase in the coefficient of friction is achieved by DIAGRIP® dispersion coatings of electrolessly or electroplated nickel and nickel-phosphorus layers with embedded hard materials. Diamond, in particular, has proven itself as a hard material in grain sizes from about 5 μm up to 35 μm, for special applications also up to 80 µm.

Friction-enhancing surfaces in various forms are used primarily in the automotive industry for crankshafts and camshafts. Premium manufacturers also use these surfaces in steering, chassis or gearboxes. Fulfilling particularly high requirements in motor sports is proof of the performance of such coatings. Furthermore, they can be found in wind turbines, where they perform well due to the achievable savings in component mass, as well as the good corrosion resistance through the use of the nickel-phosphorus alloy as a coating material. DIAGRIP®-Beschichtungen lassen sich coatings can be used to construct vibration-resistant and durable flange connections. erzielen.

![]() PRODUCT SYSTEM SHEET

PRODUCT SYSTEM SHEET

The dispersion coatings for increasing the coefficients of friction are available with different sizes of polyhedral, sharp-edged diamonds. The size of the diamonds to be used depends on the roughness of the surface of the friction pairings. The best possible results are achieved with surfaces with low roughness and low waviness – the result of metal processing by mechanical methods such as turning, milling, grinding.

Both rough and wavy surfaces reduce the actual effective contact area between the friction-enhancing dispersion layer and the component surfaces of the friction pair. The following diamond grit sizes and filling grades are offered as standard:

| Functional properties | Friction-enhancing diamond coating DIAGRIP® |

| Designation | DIAGRIP® 10 | DIAGRIP®25 | DIAGRIP®35 |

| Average particle size | 10 μm | 25 μm | 35 μm |

| Coating rate | 15 % and 30 % | 15 % and 30 % | 15 % and 30 % |

| Layer material | Layer material |

| Hardness of coating matrix | 550 – 950 HV0,1 |

| Layer thickness of the matrix (electroless nickel) | 5 – 8 μm | 13 – 17 μm | 14 – 22 μm |

| Layer thickness of the matrix (electroplated nickel) | up to several hundred microns |

| Base material for discs and foils | Copper, copper with insulating intermediate layer, steel and spring steel from 0.05 to several millimetres material thickness |

The thickness of the nickel layer is selected so that the diamond particles protrude sufficiently far from the nickel layer and can thus reliably create a material bond with the counterpart of the friction pairing.

Another parameter of the dispersion layer is provided by the electrolessly embedded nickel layer used with phosphorus contents between 1 % and up to 13 %, available in three state forms:

> Low phosphorous content – 1 % to 5 % / high deposition hardness / low corrosion resistance

> Medium phosphorous content – 5 % to 10 % / medium deposition hardness / high corrosion resistance

> High phosphorous content – 10 % to 13 % / low deposition hardness / high corrosion resistance

The phosphorous content determines the basic hardness of the nickel layer, the maximum hardness that can be achieved using temperature treatment, and the corrosion resistance.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

For special applications, or for special shaping needs of the friction pairing, it is possible to apply the nickel dispersion layer directly to components to create the friction pairing. It is strongly recommended to coordinate the choice of materials and the shaping with the manufacturer of the nickel dispersion layer.

The coefficient of friction for the surface can be used as a characteristic value for the quality of the friction-enhancing dispersion coating DIAGRIP®. However, this value depends primarily on the applied contact pressure. Usual characteristic values are between about μ = 0.5 and μ = 0.8. This results in an increase in the coefficient of friction compared to about μ = 0.3 without the use of the layers which causes an increase in the transmittable forces or torques by a factor of 3 to 4.

REQUIREMENTS FOR INCREASING THE COEFFICIENT OF FRICTION USING DISPERSION COATINGS

> Contact surfaces for the transmission of forces and torques – the amounts of force and torque to be transmitted are directly associated with the (microscopic) area percentages of the partner components or the geometric adaptation of the two partner components

> Design of contact surfaces– the efficiency of force and torque transmission depends on the actual (microscopic) contact surfaces. The roughness of the contact surfaces and the orientation of machining structures such as turning or grinding grooves play a role here.

> Hardness of the surface of the contact surfaces – the interlocking between the diamonds of the friction-enhancing dispersion coating (usually a nickel or nickel-phosphorus layer) and the surface of the component

> Coating of the contact surfaces with foreign substances – he type of interlocking between friction-enhancing surfaces and contact partners are not changed or are only changed insignificantly by the presence of foreign substances (oil, grease, dirt).

> Assembly and disassembly of contact surfaces – the contact surfaces can be easily separated from one another after disconnecting screw fittings or removing pressure

> Design – the use of dispersion coatings to transmit force and torque does not require changes to the design of the components. This applies, in particular, to the use of films with a dispersion layer applied to one or preferably both sides.

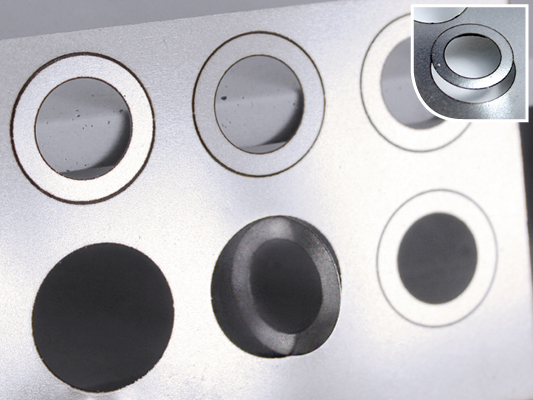

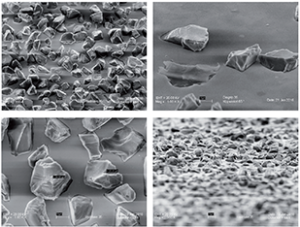

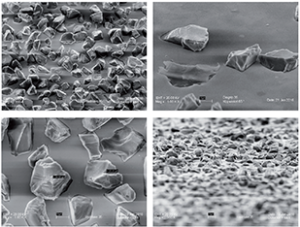

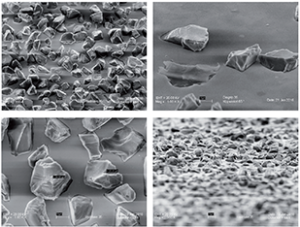

View of the nickel dispersion layer as a frictional foil DIAGRIP® 35 with embedded diamond particles

![]() PRODUCT

PRODUCT

SYSTEM SHEET

SOLUTION EXAMPLES

THERE IS ALWAYS A CUSTOM-TAILORED SOLUTION

The requirements are different for each component. Our DIAGRIP coating process is flexible.

We adapt to your needs. Please feel free to get in touch.

Large-format friction shims are used up to diameters of more than 2000 mm. Due to the segmentation of the discs and intelligent fixing profiles in the segments, they can be easily handled during assembly. The thickness of the discs can range from 0.1 mm to 50 mm. The discs and segments can be reused if handled properly.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

AT A GLANCE

Dispersion coating of nickel-phosphorus with diamond on substrate material (C75/C100/CU/Ni/stainless steel/plastic):

CHARACTERISTIC:

> Increased adhesion, detachable contact surface

> Adjustable hardness of the nickel-phosphorous layer (approx. 550 HV0,1 to approx. 950 HV0,1)

> High corrosion resistance

> Good contour accuracy and very even thickness of the nickel coating

> Can be used with existing designs

APPLICATION:

Transmission of forces and torques in functional systems for the production of force-locking composite systems with screw connection, press connection or flange connection.

COATING CHARACTERISTICS:

Nickel-phosphorus layer from approx. 5 μm to approx. 22 μm with diamond grain size between 10 µm and 35 µm (layer thickness/grain size matched to each other), larger grain sizes (> 35 µm – 80 µm) as special solution

Friction value μ = 0.5 – 0.8

SUBSTRATE CHARACTERISTICS:

Electroplatable base material with adapted, defined roughness

![]() PRODUCT SYSTEM SHEET

PRODUCT SYSTEM SHEET

ADVANTAGES

+ Increase in the transmittable forces by 0.5 – 0.8 μ and torques of a connection via flange unit, as well as resulting reduction in component sizes and weights

+ 3 to 4 times higher transmittable torque

+ Direct coating, as a friction shim or foil

+ Can be used with components in any shape & size

+ Increase in the safety factor

+ Reduction in cost for individual components

+ Easy handling

+ Not sensitive to lubricants

+ Normally reusable after disassembly

+ Usable without additional work

Coatings based on nickel and nickel-phosphorus stand out for combining multiple important characteristics, and for allowing these characteristics to be adapted to specific applications based on their composition and/or heat treatment. This can be illustrated by means of a network diagram for qualitative evaluation, on the basis of which the user can select the required properties.

![]() PRODUCT SYSTEM SHEET

PRODUCT SYSTEM SHEET

APPLICATIONS

The dynamic transmission of mechanical forces and torques in machines can be achieved, among other things, by connecting the drive and machine elements by pressing two (usually rotating) surfaces onto each other. Depending on the design of the machines, permanently working but detachable or cyclically working transmission designs are used. Examples include flange connections, face press connections, shaft-hub connections, but also screw connections, which are usually permanent. Cyclically operating systems for power and torque transmission, for example, consist of two discs pressed onto each other.

In all cases, the efficiency of the power or torque transmission is subject to the requirement that friction is largely eliminated..The relevant parameters of power transmission include, above all, the available surface area of the two contact partners (drive and counterpart). The more efficiently friction or slip is prevented, the smaller and thus lighter the two contact partners can be designed to be – increasing the coefficient of friction thus offers a decisive contribution to energy and material savings in system and machine construction. The increase in the coefficient of friction is achieved by DIAGRIP® dispersion coatings of electrolessly or electroplated nickel and nickel-phosphorus layers with embedded hard materials. Diamond, in particular, has proven itself as a hard material in grain sizes from about 5 μm up to 35 μm, for special applications also up to 80 µm.

Friction-enhancing surfaces in various forms are used primarily in the automotive industry for crankshafts and camshafts. Premium manufacturers also use these surfaces in steering, chassis or gearboxes. Fulfilling particularly high requirements in motor sports is proof of the performance of such coatings. Furthermore, they can be found in wind turbines, where they perform well due to the achievable savings in component mass, as well as the good corrosion resistance through the use of the nickel-phosphorus alloy as a coating material. DIAGRIP®-Beschichtungen lassen sich coatings can be used to construct vibration-resistant and durable flange connections. erzielen.

![]() PRODUCT SYSTEM SHEET

PRODUCT SYSTEM SHEET

PARAMETERS

The dispersion coatings for increasing the coefficients of friction are available with different sizes of polyhedral, sharp-edged diamonds. The size of the diamonds to be used depends on the roughness of the surface of the friction pairings. The best possible results are achieved with surfaces with low roughness and low waviness – the result of metal processing by mechanical methods such as turning, milling, grinding.

Both rough and wavy surfaces reduce the actual effective contact area between the friction-enhancing dispersion layer and the component surfaces of the friction pair. The following diamond grit sizes and filling grades are offered as standard:

| Functional properties | Friction-enhancing diamond coating DIAGRIP® |

| Designation | DIAGRIP® 10 | DIAGRIP®25 | DIAGRIP®35 |

| Average particle size | 10 μm | 25 μm | 35 μm |

| Coating rate | 15 % and 30 % | 15 % and 30 % | 15 % and 30 % |

| Layer material | Layer material |

| Hardness of coating matrix | 550 – 950 HV0,1 |

| Layer thickness of the matrix (electroless nickel) | 5 – 8 μm | 13 – 17 μm | 14 – 22 μm |

| Layer thickness of the matrix (electroplated nickel) | up to several hundred microns |

| Base material for discs and foils | Copper, copper with insulating intermediate layer, steel and spring steel from 0.05 to several millimetres material thickness |

The thickness of the nickel layer is selected so that the diamond particles protrude sufficiently far from the nickel layer and can thus reliably create a material bond with the counterpart of the friction pairing.

Another parameter of the dispersion layer is provided by the electrolessly embedded nickel layer used with phosphorus contents between 1 % and up to 13 %, available in three state forms:

> Low phosphorous content – 1 % to 5 % / high deposition hardness / low corrosion resistance

> Medium phosphorous content – 5 % to 10 % / medium deposition hardness / high corrosion resistance

> High phosphorous content – 10 % to 13 % / low deposition hardness / high corrosion resistance

The phosphorous content determines the basic hardness of the nickel layer, the maximum hardness that can be achieved using temperature treatment, and the corrosion resistance.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

For special applications, or for special shaping needs of the friction pairing, it is possible to apply the nickel dispersion layer directly to components to create the friction pairing. It is strongly recommended to coordinate the choice of materials and the shaping with the manufacturer of the nickel dispersion layer.

The coefficient of friction for the surface can be used as a characteristic value for the quality of the friction-enhancing dispersion coating DIAGRIP®. However, this value depends primarily on the applied contact pressure. Usual characteristic values are between about μ = 0.5 and μ = 0.8. This results in an increase in the coefficient of friction compared to about μ = 0.3 without the use of the layers which causes an increase in the transmittable forces or torques by a factor of 3 to 4.

REQUIREMENTS

REQUIREMENTS FOR INCREASING THE COEFFICIENT OF FRICTION USING DISPERSION COATINGS

> Contact surfaces for the transmission of forces and torques – the amounts of force and torque to be transmitted are directly associated with the (microscopic) area percentages of the partner components or the geometric adaptation of the two partner components

> Design of contact surfaces– the efficiency of force and torque transmission depends on the actual (microscopic) contact surfaces. The roughness of the contact surfaces and the orientation of machining structures such as turning or grinding grooves play a role here.

> Hardness of the surface of the contact surfaces – the interlocking between the diamonds of the friction-enhancing dispersion coating (usually a nickel or nickel-phosphorus layer) and the surface of the component

> Coating of the contact surfaces with foreign substances – he type of interlocking between friction-enhancing surfaces and contact partners are not changed or are only changed insignificantly by the presence of foreign substances (oil, grease, dirt).

> Assembly and disassembly of contact surfaces – the contact surfaces can be easily separated from one another after disconnecting screw fittings or removing pressure

> Design – the use of dispersion coatings to transmit force and torque does not require changes to the design of the components. This applies, in particular, to the use of films with a dispersion layer applied to one or preferably both sides.

View of the nickel dispersion layer as a frictional foil DIAGRIP® 35 with embedded diamond particles

![]() PRODUCT

PRODUCT

SYSTEM SHEET

SOLUTION EXAMPLES

THERE IS ALWAYS A CUSTOM-TAILORED SOLUTION

The requirements are different for each component. Our DIAGRIP coating process is flexible.

We adapt to your needs. Please feel free to get in touch.

Large-format friction shims are used up to diameters of more than 2000 mm. Due to the segmentation of the discs and intelligent fixing profiles in the segments, they can be easily handled during assembly. The thickness of the discs can range from 0.1 mm to 50 mm. The discs and segments can be reused if handled properly.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

AT A GLANCE

Dispersion coating of nickel-phosphorus with diamond on substrate material (C75/C100/CU/Ni/stainless steel/plastic):

CHARACTERISTIC:

> Increased adhesion, detachable contact surface

> Adjustable hardness of the nickel-phosphorous layer (approx. 550 HV0,1 to approx. 950 HV0,1)

> High corrosion resistance

> Good contour accuracy and very even thickness of the nickel coating

> Can be used with existing designs

APPLICATION:

Transmission of forces and torques in functional systems for the production of force-locking composite systems with screw connection, press connection or flange connection.

COATING CHARACTERISTICS:

Nickel-phosphorus layer from approx. 5 μm to approx. 22 μm with diamond grain size between 10 µm and 35 µm (layer thickness/grain size matched to each other), larger grain sizes (> 35 µm – 80 µm) as special solution

Friction value μ = 0.5 – 0.8

SUBSTRATE CHARACTERISTICS:

Electroplatable base material with adapted, defined roughness

![]() PRODUCT SYSTEM SHEET

PRODUCT SYSTEM SHEET

ADVANTAGES

+ Increase in the transmittable forces by 0.5 – 0.8 μ and torques of a connection via flange unit, as well as resulting reduction in component sizes and weights

+ 3 to 4 times higher transmittable torque

+ Direct coating, as a friction shim or foil

+ Can be used with components in any shape & size

+ Increase in the safety factor

+ Reduction in cost for individual components

+ Easy handling

+ Not sensitive to lubricants

+ Normally reusable after disassembly

+ Usable without additional work

Coatings based on nickel and nickel-phosphorus stand out for combining multiple important characteristics, and for allowing these characteristics to be adapted to specific applications based on their composition and/or heat treatment. This can be illustrated by means of a network diagram for qualitative evaluation, on the basis of which the user can select the required properties.

![]() PRODUCT SYSTEM SHEET

PRODUCT SYSTEM SHEET

APPLICATIONS

The dynamic transmission of mechanical forces and torques in machines can be achieved, among other things, by connecting the drive and machine elements by pressing two (usually rotating) surfaces onto each other. Depending on the design of the machines, permanently working but detachable or cyclically working transmission designs are used. Examples include flange connections, face press connections, shaft-hub connections, but also screw connections, which are usually permanent. Cyclically operating systems for power and torque transmission, for example, consist of two discs pressed onto each other.

In all cases, the efficiency of the power or torque transmission is subject to the requirement that friction is largely eliminated..The relevant parameters of power transmission include, above all, the available surface area of the two contact partners (drive and counterpart). The more efficiently friction or slip is prevented, the smaller and thus lighter the two contact partners can be designed to be – increasing the coefficient of friction thus offers a decisive contribution to energy and material savings in system and machine construction. The increase in the coefficient of friction is achieved by DIAGRIP® dispersion coatings of electrolessly or electroplated nickel and nickel-phosphorus layers with embedded hard materials. Diamond, in particular, has proven itself as a hard material in grain sizes from about 5 μm up to 35 μm, for special applications also up to 80 µm.

Friction-enhancing surfaces in various forms are used primarily in the automotive industry for crankshafts and camshafts. Premium manufacturers also use these surfaces in steering, chassis or gearboxes. Fulfilling particularly high requirements in motor sports is proof of the performance of such coatings. Furthermore, they can be found in wind turbines, where they perform well due to the achievable savings in component mass, as well as the good corrosion resistance through the use of the nickel-phosphorus alloy as a coating material. DIAGRIP®-Beschichtungen lassen sich coatings can be used to construct vibration-resistant and durable flange connections. erzielen.

![]() PRODUCT SYSTEM SHEET

PRODUCT SYSTEM SHEET

PARAMETERS

The dispersion coatings for increasing the coefficients of friction are available with different sizes of polyhedral, sharp-edged diamonds. The size of the diamonds to be used depends on the roughness of the surface of the friction pairings. The best possible results are achieved with surfaces with low roughness and low waviness – the result of metal processing by mechanical methods such as turning, milling, grinding.

Both rough and wavy surfaces reduce the actual effective contact area between the friction-enhancing dispersion layer and the component surfaces of the friction pair. The following diamond grit sizes and filling grades are offered as standard:

| Functional properties | Friction-enhancing diamond coating DIAGRIP® |

| Designation | DIAGRIP® 10 | DIAGRIP®25 | DIAGRIP®35 |

| Average particle size | 10 μm | 25 μm | 35 μm |

| Coating rate | 15 % and 30 % | 15 % and 30 % | 15 % and 30 % |

| Layer material | Layer material |

| Hardness of coating matrix | 550 – 950 HV0,1 |

| Layer thickness of the matrix (electroless nickel) | 5 – 8 μm | 13 – 17 μm | 14 – 22 μm |

| Layer thickness of the matrix (electroplated nickel) | up to several hundred microns |

| Base material for discs and foils | Copper, copper with insulating intermediate layer, steel and spring steel from 0.05 to several millimetres material thickness |

The thickness of the nickel layer is selected so that the diamond particles protrude sufficiently far from the nickel layer and can thus reliably create a material bond with the counterpart of the friction pairing.

Another parameter of the dispersion layer is provided by the electrolessly embedded nickel layer used with phosphorus contents between 1 % and up to 13 %, available in three state forms:

> Low phosphorous content – 1 % to 5 % / high deposition hardness / low corrosion resistance

> Medium phosphorous content – 5 % to 10 % / medium deposition hardness / high corrosion resistance

> High phosphorous content – 10 % to 13 % / low deposition hardness / high corrosion resistance

The phosphorous content determines the basic hardness of the nickel layer, the maximum hardness that can be achieved using temperature treatment, and the corrosion resistance.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

For special applications, or for special shaping needs of the friction pairing, it is possible to apply the nickel dispersion layer directly to components to create the friction pairing. It is strongly recommended to coordinate the choice of materials and the shaping with the manufacturer of the nickel dispersion layer.

The coefficient of friction for the surface can be used as a characteristic value for the quality of the friction-enhancing dispersion coating DIAGRIP®. However, this value depends primarily on the applied contact pressure. Usual characteristic values are between about μ = 0.5 and μ = 0.8. This results in an increase in the coefficient of friction compared to about μ = 0.3 without the use of the layers which causes an increase in the transmittable forces or torques by a factor of 3 to 4.

REQUIREMENTS

REQUIREMENTS FOR INCREASING THE COEFFICIENT OF FRICTION USING DISPERSION COATINGS

> Contact surfaces for the transmission of forces and torques – the amounts of force and torque to be transmitted are directly associated with the (microscopic) area percentages of the partner components or the geometric adaptation of the two partner components

> Design of contact surfaces– the efficiency of force and torque transmission depends on the actual (microscopic) contact surfaces. The roughness of the contact surfaces and the orientation of machining structures such as turning or grinding grooves play a role here.

> Hardness of the surface of the contact surfaces – the interlocking between the diamonds of the friction-enhancing dispersion coating (usually a nickel or nickel-phosphorus layer) and the surface of the component

> Coating of the contact surfaces with foreign substances – he type of interlocking between friction-enhancing surfaces and contact partners are not changed or are only changed insignificantly by the presence of foreign substances (oil, grease, dirt).

> Assembly and disassembly of contact surfaces – the contact surfaces can be easily separated from one another after disconnecting screw fittings or removing pressure

> Design – the use of dispersion coatings to transmit force and torque does not require changes to the design of the components. This applies, in particular, to the use of films with a dispersion layer applied to one or preferably both sides.

View of the nickel dispersion layer as a frictional foil DIAGRIP® 35 with embedded diamond particles

![]() PRODUCT

PRODUCT

SYSTEM SHEET

Schematic representation of the friction-enhancing system consisting of dispersion layer and counterpart of the friction pairing