COATING

& FINISHING

PRODUCT SPECIFICATIONS

The requirements are different for every surface. Our coating process is flexible and has an adjustable degree of hardness. We adapt to your needs. Please feel free to get in touch.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

Dispersion coating based on nickel and nickel-phosphorus:

CHARACTERISTIC:

> Wear resistant layer for machining and finishing

> Adjustable hardness of the nickel-phosphorous layer (approx. 550 HV0.1 to approx. 1,100 HV0.1)

> High corrosion resistance

> Perfect contour accuracy and very even layer thickness with electroless nickel

> High layer thicknesses when using nickel electroplating

APPLICATION:

For coating of machining tools

COATING CHARACTERISTICS:

Nickel-phosphorus layer from approx. 5 μm to approx. 22 µm with dispersion materials

Particle sizes from 2 μm – 500 μm

SUBSTRATE CHARACTERISTICS:

The substrate material must be suitable for electroplating to achieve the very good adhesion of the coating to the substrate.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

+ The optimal solution for tools

+ For machining and finishing

+ Thin-film systems ( < 10 μm)

+ Thick-film systems ( < 500 μm)

+ Long tool life and regenerable

+ Freely configurable cutting power

+ Versatile use in almost any kind of tool

+ Cost reduction compared to commonly used tool materials

+ Use without design changes

+ Easy to handle

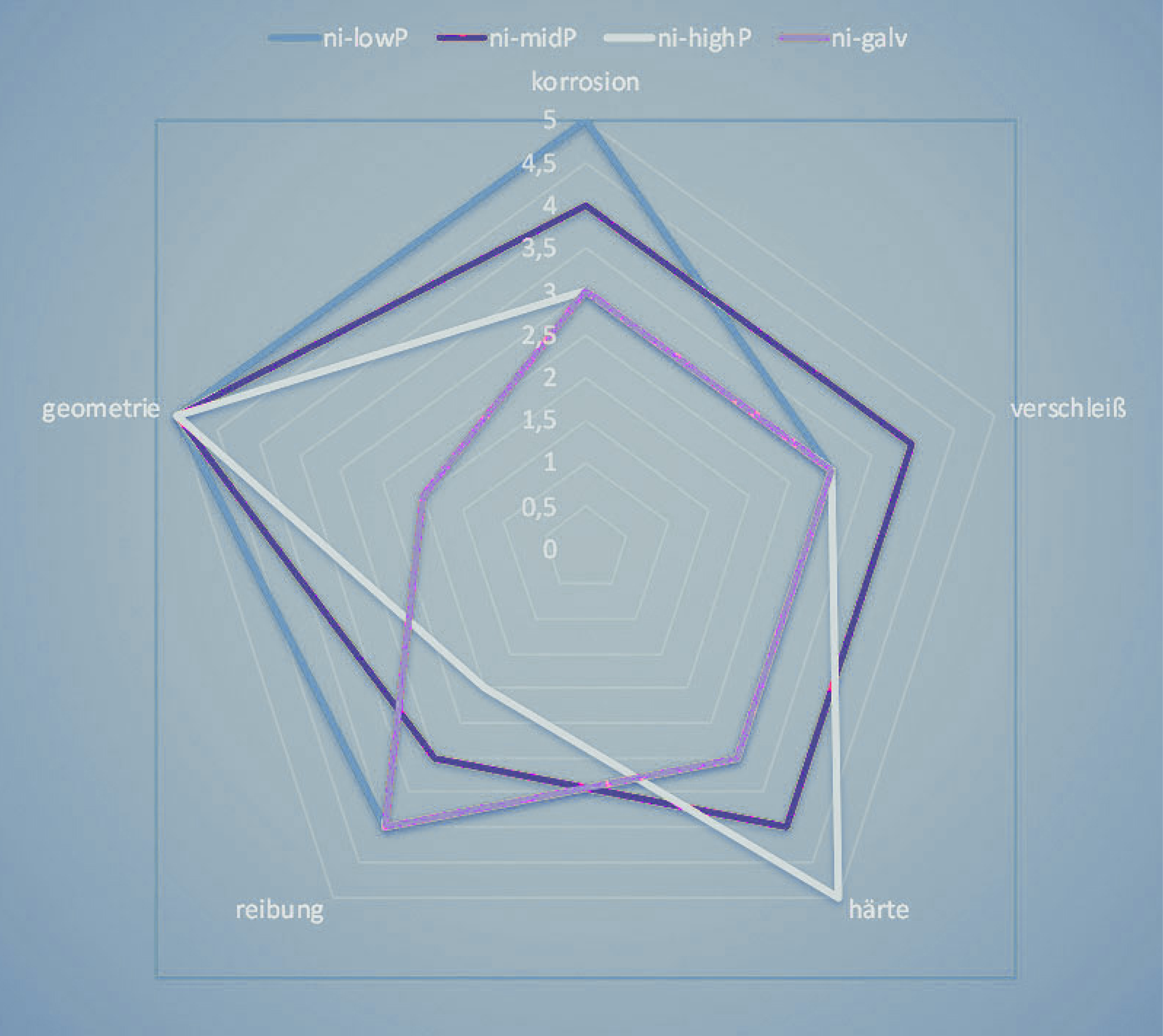

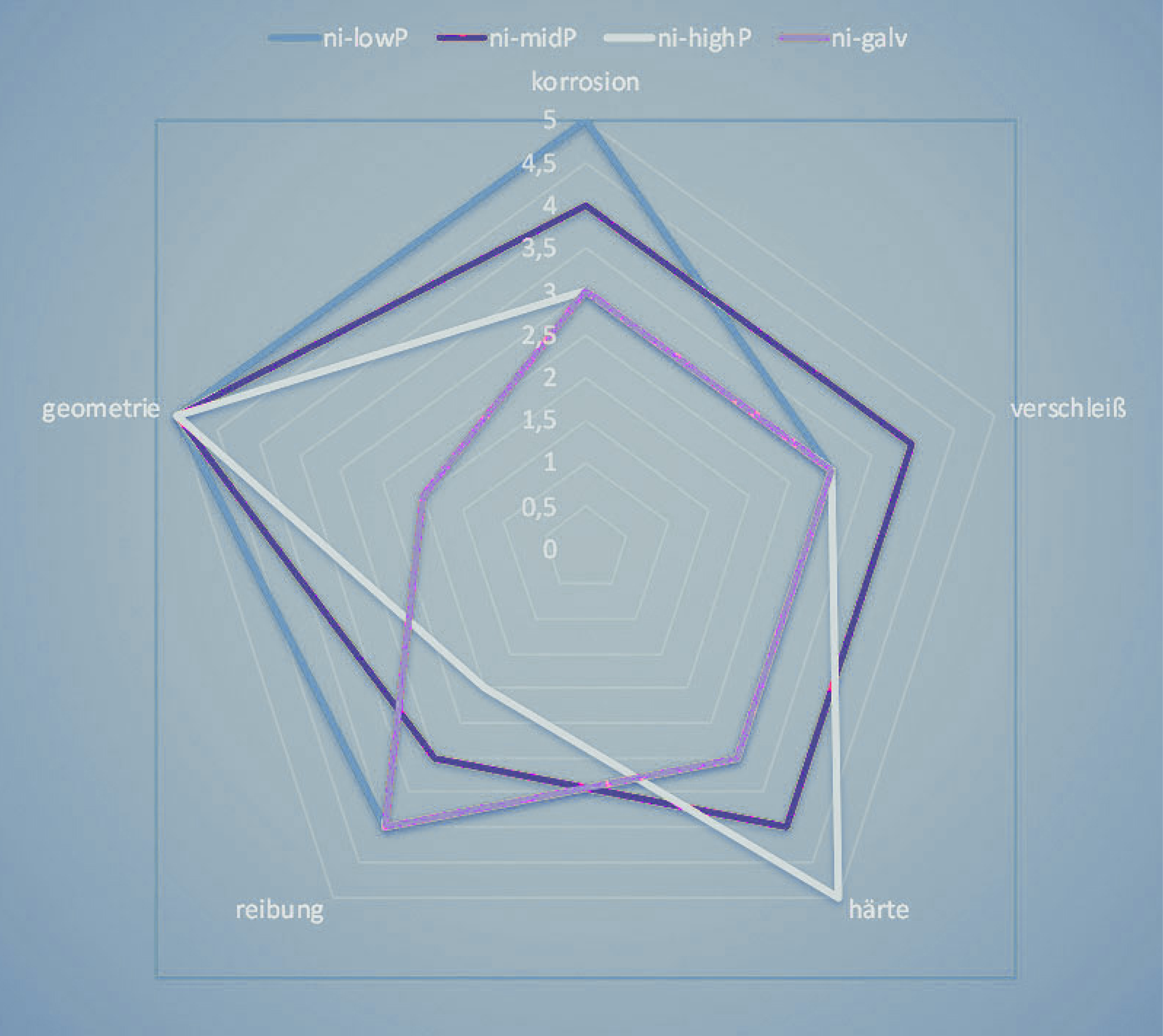

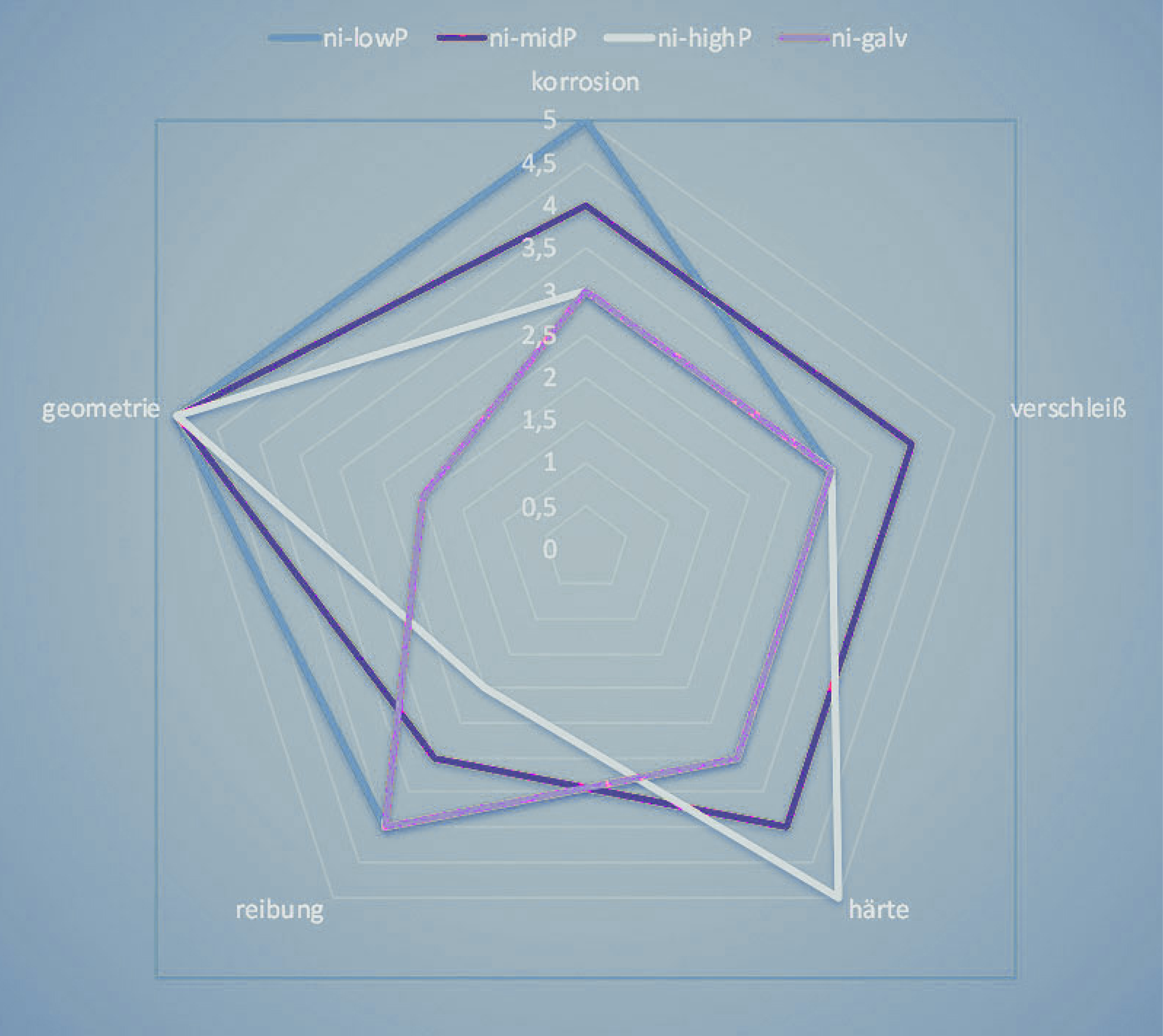

DIAFIN®dispersion coatings based on nickel and nickel-phosphorous stand out for combining several important characteristics, or for making it possible to adapt their characteristics depending on their composition and/or heat treatment to the requirements of specific applications. This can be illustrated by means of a network diagram for qualitative evaluation, on the basis of which the user can select the required properties.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

Tools for the mechanical processing of metallic and non-metallic substrates must have good resistance to friction and wear, combined with a certain degree of corrosion resistance to various environmental influences. Nickel and nickel alloys, in particular, meet these challenges to a high degree.

The DIAFIN® coating system is the solution for creating surfaces on tools for machining and finishing materials. Depending on the surface requirements, the DIAFIN® coating is based on an electroless nickel-phosphorus alloy or electroplated nickel.

The hardness and, above all, the friction and wear properties can be adapted to the respective task within a wide range through the incorporation of dispersion substances or heat treatment. The hardness of a DIAFIN® coating can be adjusted to values between about 550 HV and 1,100 HV when electroless nickel is used, depending on the phosphorus content and post-treatment. Cubic boron nitride (cBN) or diamond are primarily used as the embedded particles in DIAFIN® dispersion coatings. The layers are deposited in thicknesses from about 10 µm to several hundred micrometres. In addition to a good mechanical stability, the coatings are also characterised by a very high resistance to corrosion.

Typical applications for DIAFIN® coatings:

> Extraction or dressing tools for measurement gages for threads or fittings, plug gages

> Drill bits, reamers or honing tools

> Tools for grinding, finishing and super-finishing

> Belts for grinding or extraction.

DIAFIN® coatings are suitable for further conditioning. For example, the application of an additional DIASHIELD® layer in a thickness between 3 µm and 20 µm reduces the surface roughness and optimises the running-in behaviour.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

In the case of a DIAFIN® dispersion coating, the thickness of the nickel layer is selected in such a way that the particles (e.g. cBN and diamond) are reliably incorporated homogeneously in the coating.

The required layer thicknesses are listed in the following table.

| Functional properties | Friction-enhancing DIAFIN® diamond coating |

| Designation | DIAFIN® | DIAFIN® | DIAFIN® |

| Average particle size | 2-10 μm | 11-250 μm | 250-500 μm |

| Coating rate | 15 % and 30 % | 15 % and 30 % | 15 % and 30 % |

| Layer material | Electroless nickel-phosphorus or electroplated nickel or nickel-phosphorus. |

| Hardness of coating matrix | 550 – 1,100 HV0.1 |

| Layer thickness of the matrix (electroless nickel) | 5 – 50 μm | 11 – 250 μm | 250 – 500 μm |

| Layer thickness of the matrix (electroplated nickel) | up to several hundred microns |

A characteristic value for the properties of the coating is provided by electrolessly deposited nickel (if used) with phosphorus contents between 1 % and up to 13 %, available in three forms:

> Low phosphorous content – 2 % to 5 % / high deposition hardness / low corrosion resistance

> Medium phosphorous content – 5 % to 10 % / medium deposition hardness / high corrosion resistance

> High phosphorous content –10 % to 13 % / low deposition hardness / high corrosion resistance

10 % to 13 % / low deposition hardness / high corrosion resistance

![]() PRODUCT

PRODUCT

SYSTEM SHEET

PREREQUISITES FOR DIAFIN COATINGS:

The substrate material must be suitable for electroplating to achieve the very good adhesion of the coating to the substrate. The suitability for electroplating with DIAFIN® must be clarified with the client. In addition, the substrate must have sufficient load-bearing capacity to prevent excessive deformation and the resulting high mechanical stress (in extreme cases up to mechanical destruction) of the coating.

When using a DIAFIN® dispersion coating, the interlocking between the hard materials (e.g. cBN and diamond) of the coating (nickel or nickel-phosphorus) and the surface of the component is determined by the surface hardness of the substrate. A higher surface hardness may make it more difficult to seed the substrate surface (i.e. to produce an even and well-adhering nickel dispersion layer). A lower surface hardness increases the shearing (in the form of material wear) of material of the component and thereby the occurrence of (friction) wear.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

SOLUTION EXAMPLES

The requirements are different for every surface. Our coating process is flexible and has an adjustable degree of hardness. We adapt to your needs. Please feel free to get in touch.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

AT A GLANCE

Dispersion coating based on nickel and nickel-phosphorus:

CHARACTERISTIC:

> Wear resistant layer for machining and finishing

> Adjustable hardness of the nickel-phosphorous layer (approx. 550 HV0.1 to approx. 1,100 HV0.1)

> High corrosion resistance

> Perfect contour accuracy and very even layer thickness with electroless nickel

> High layer thicknesses when using nickel electroplating

APPLICATION:

For coating of machining tools

COATING CHARACTERISTICS:

Nickel-phosphorus layer from approx. 5 μm to approx. 22 µm with dispersion materials

Particle sizes from 2 μm – 500 μm

SUBSTRATE CHARACTERISTICS:

The substrate material must be suitable for electroplating to achieve the very good adhesion of the coating to the substrate.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

ADVANTAGES

+ The optimal solution for tools

+ For machining and finishing

+ Thin-film systems ( < 10 μm)

+ Thick-film systems ( < 500 μm)

+ Long tool life and regenerable

+ Freely configurable cutting power

+ Versatile use in almost any kind of tool

+ Cost reduction compared to commonly used tool materials

+ Use without design changes

+ Easy to handle

DIAFIN®dispersion coatings based on nickel and nickel-phosphorous stand out for combining several important characteristics, or for making it possible to adapt their characteristics depending on their composition and/or heat treatment to the requirements of specific applications. This can be illustrated by means of a network diagram for qualitative evaluation, on the basis of which the user can select the required properties.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

APPLICATIONS

Tools for the mechanical processing of metallic and non-metallic substrates must have good resistance to friction and wear, combined with a certain degree of corrosion resistance to various environmental influences. Nickel and nickel alloys, in particular, meet these challenges to a high degree.

The DIAFIN® coating system is the solution for creating surfaces on tools for machining and finishing materials. Depending on the surface requirements, the DIAFIN® coating is based on an electroless nickel-phosphorus alloy or electroplated nickel.

The hardness and, above all, the friction and wear properties can be adapted to the respective task within a wide range through the incorporation of dispersion substances or heat treatment. The hardness of a DIAFIN® coating can be adjusted to values between about 550 HV and 1,100 HV when electroless nickel is used, depending on the phosphorus content and post-treatment. Cubic boron nitride (cBN) or diamond are primarily used as the embedded particles in DIAFIN® dispersion coatings. The layers are deposited in thicknesses from about 10 µm to several hundred micrometres. In addition to a good mechanical stability, the coatings are also characterised by a very high resistance to corrosion.

Typical applications for DIAFIN® coatings:

> Extraction or dressing tools for measurement gages for threads or fittings, plug gages

> Drill bits, reamers or honing tools

> Tools for grinding, finishing and super-finishing

> Belts for grinding or extraction.

DIAFIN® coatings are suitable for further conditioning. For example, the application of an additional DIASHIELD® layer in a thickness between 3 µm and 20 µm reduces the surface roughness and optimises the running-in behaviour.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

PARAMETERS

In the case of a DIAFIN® dispersion coating, the thickness of the nickel layer is selected in such a way that the particles (e.g. cBN and diamond) are reliably incorporated homogeneously in the coating.

The required layer thicknesses are listed in the following table.

| Functional properties | Friction-enhancing DIAFIN® diamond coating |

| Designation | DIAFIN® | DIAFIN® | DIAFIN® |

| Average particle size | 2-10 μm | 11-250 μm | 250-500 μm |

| Coating rate | 15 % and 30 % | 15 % and 30 % | 15 % and 30 % |

| Layer material | Electroless nickel-phosphorus or electroplated nickel or nickel-phosphorus. |

| Hardness of coating matrix | 550 – 1,100 HV0.1 |

| Layer thickness of the matrix (electroless nickel) | 5 – 50 μm | 11 – 250 μm | 250 – 500 μm |

| Layer thickness of the matrix (electroplated nickel) | up to several hundred microns |

A characteristic value for the properties of the coating is provided by electrolessly deposited nickel (if used) with phosphorus contents between 1 % and up to 13 %, available in three forms:

> Low phosphorous content – 2 % to 5 % / high deposition hardness / low corrosion resistance

> Medium phosphorous content – 5 % to 10 % / medium deposition hardness / high corrosion resistance

> High phosphorous content –10 % to 13 % / low deposition hardness / high corrosion resistance

10 % to 13 % / low deposition hardness / high corrosion resistance

![]() PRODUCT

PRODUCT

SYSTEM SHEET

REQUIREMENTS

PREREQUISITES FOR DIAFIN COATINGS:

The substrate material must be suitable for electroplating to achieve the very good adhesion of the coating to the substrate. The suitability for electroplating with DIAFIN® must be clarified with the client. In addition, the substrate must have sufficient load-bearing capacity to prevent excessive deformation and the resulting high mechanical stress (in extreme cases up to mechanical destruction) of the coating.

When using a DIAFIN® dispersion coating, the interlocking between the hard materials (e.g. cBN and diamond) of the coating (nickel or nickel-phosphorus) and the surface of the component is determined by the surface hardness of the substrate. A higher surface hardness may make it more difficult to seed the substrate surface (i.e. to produce an even and well-adhering nickel dispersion layer). A lower surface hardness increases the shearing (in the form of material wear) of material of the component and thereby the occurrence of (friction) wear.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

SOLUTION EXAMPLES

The requirements are different for every surface. Our coating process is flexible and has an adjustable degree of hardness. We adapt to your needs. Please feel free to get in touch.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

AT A GLANCE

Dispersion coating based on nickel and nickel-phosphorus:

CHARACTERISTIC:

> Wear resistant layer for machining and finishing

> Adjustable hardness of the nickel-phosphorous layer (approx. 550 HV0.1 to approx. 1,100 HV0.1)

> High corrosion resistance

> Perfect contour accuracy and very even layer thickness with electroless nickel

> High layer thicknesses when using nickel electroplating

APPLICATION:

For coating of machining tools

COATING CHARACTERISTICS:

Nickel-phosphorus layer from approx. 5 μm to approx. 22 µm with dispersion materials

Particle sizes from 2 μm – 500 μm

SUBSTRATE CHARACTERISTICS:

The substrate material must be suitable for electroplating to achieve the very good adhesion of the coating to the substrate.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

ADVANTAGES

+ The optimal solution for tools

+ For machining and finishing

+ Thin-film systems ( < 10 μm)

+ Thick-film systems ( < 500 μm)

+ Long tool life and regenerable

+ Freely configurable cutting power

+ Versatile use in almost any kind of tool

+ Cost reduction compared to commonly used tool materials

+ Use without design changes

+ Easy to handle

DIAFIN®dispersion coatings based on nickel and nickel-phosphorous stand out for combining several important characteristics, or for making it possible to adapt their characteristics depending on their composition and/or heat treatment to the requirements of specific applications. This can be illustrated by means of a network diagram for qualitative evaluation, on the basis of which the user can select the required properties.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

APPLICATIONS

Tools for the mechanical processing of metallic and non-metallic substrates must have good resistance to friction and wear, combined with a certain degree of corrosion resistance to various environmental influences. Nickel and nickel alloys, in particular, meet these challenges to a high degree.

The DIAFIN® coating system is the solution for creating surfaces on tools for machining and finishing materials. Depending on the surface requirements, the DIAFIN® coating is based on an electroless nickel-phosphorus alloy or electroplated nickel.

The hardness and, above all, the friction and wear properties can be adapted to the respective task within a wide range through the incorporation of dispersion substances or heat treatment. The hardness of a DIAFIN® coating can be adjusted to values between about 550 HV and 1,100 HV when electroless nickel is used, depending on the phosphorus content and post-treatment. Cubic boron nitride (cBN) or diamond are primarily used as the embedded particles in DIAFIN® dispersion coatings. The layers are deposited in thicknesses from about 10 µm to several hundred micrometres. In addition to a good mechanical stability, the coatings are also characterised by a very high resistance to corrosion.

Typical applications for DIAFIN® coatings:

> Extraction or dressing tools for measurement gages for threads or fittings, plug gages

> Drill bits, reamers or honing tools

> Tools for grinding, finishing and super-finishing

> Belts for grinding or extraction.

DIAFIN® coatings are suitable for further conditioning. For example, the application of an additional DIASHIELD® layer in a thickness between 3 µm and 20 µm reduces the surface roughness and optimises the running-in behaviour.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

PARAMETERS

In the case of a DIAFIN® dispersion coating, the thickness of the nickel layer is selected in such a way that the particles (e.g. cBN and diamond) are reliably incorporated homogeneously in the coating.

The required layer thicknesses are listed in the following table.

| Functional properties | Friction-enhancing DIAFIN® diamond coating |

| Designation | DIAFIN® | DIAFIN® | DIAFIN® |

| Average particle size | 2-10 μm | 11-250 μm | 250-500 μm |

| Coating rate | 15 % and 30 % | 15 % and 30 % | 15 % and 30 % |

| Layer material | Electroless nickel-phosphorus or electroplated nickel or nickel-phosphorus. |

| Hardness of coating matrix | 550 – 1,100 HV0.1 |

| Layer thickness of the matrix (electroless nickel) | 5 – 50 μm | 11 – 250 μm | 250 – 500 μm |

| Layer thickness of the matrix (electroplated nickel) | up to several hundred microns |

A characteristic value for the properties of the coating is provided by electrolessly deposited nickel (if used) with phosphorus contents between 1 % and up to 13 %, available in three forms:

> Low phosphorous content – 2 % to 5 % / high deposition hardness / low corrosion resistance

> Medium phosphorous content – 5 % to 10 % / medium deposition hardness / high corrosion resistance

> High phosphorous content –10 % to 13 % / low deposition hardness / high corrosion resistance

10 % to 13 % / low deposition hardness / high corrosion resistance

![]() PRODUCT

PRODUCT

SYSTEM SHEET

REQUIREMENTS

PREREQUISITES FOR DIAFIN COATINGS:

The substrate material must be suitable for electroplating to achieve the very good adhesion of the coating to the substrate. The suitability for electroplating with DIAFIN® must be clarified with the client. In addition, the substrate must have sufficient load-bearing capacity to prevent excessive deformation and the resulting high mechanical stress (in extreme cases up to mechanical destruction) of the coating.

When using a DIAFIN® dispersion coating, the interlocking between the hard materials (e.g. cBN and diamond) of the coating (nickel or nickel-phosphorus) and the surface of the component is determined by the surface hardness of the substrate. A higher surface hardness may make it more difficult to seed the substrate surface (i.e. to produce an even and well-adhering nickel dispersion layer). A lower surface hardness increases the shearing (in the form of material wear) of material of the component and thereby the occurrence of (friction) wear.

![]() PRODUCT

PRODUCT

SYSTEM SHEET

CONTACT